Bi-xim pwm, OEM yas ob xim molded qhov chaw

Ob-steev txhaj tshuaj molding siv ib txheej txheem los tsim cov khoom uas muaj ntau daim.Qhov no tso cai rau cov tuam txhab tsim cov khoom nyuaj dua yam tsis muaj kev pheej hmoo ntawm kev sib kis, uas yog ib qho teeb meem tshwm sim thaum sib txuas cov khoom molded los ntawm ob txoj kev sib txawv.Cov khoom tsim los ntawm kev txhaj tshuaj molding ob zaug yog qhov ruaj khov dua li cov khoom tsim los ntawm ib tus neeg uas yog molded nyias;lawv muaj kev poob siab-resistant, tsim cov ntsaws ruaj ruaj, thiab tsim cov qauv xim uas yuav tsis hnav.Raws li ib qho ntxiv lawm, cov txheej txheem ntawm kev txhaj tshuaj molding ib leeg tsis tshua kim thiab muaj txiaj ntsig ntau dua li tsim cov khoom siv ob lossis ntau cov txheej txheem sib txawv, yog li koj yuav txuag sijhawm thiab nyiaj txiag thaum tsim cov khoom lag luam zoo dua.

| Technical Parameters | |

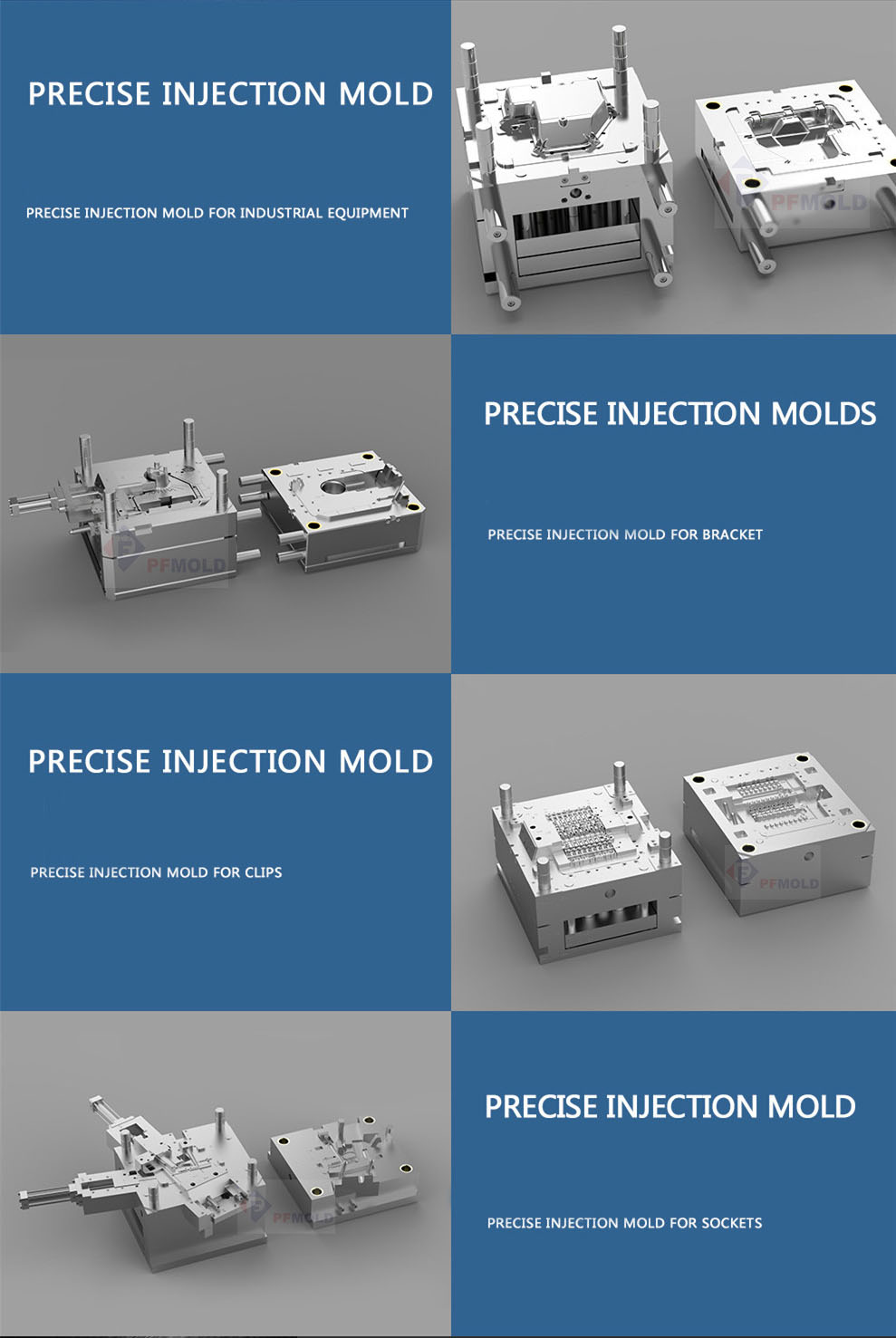

| Lub npe | Multi-xim molding qhov chaw |

| Xim: | Customized |

| Khoom siv: | Cov khoom uas xav tau cov khoom sib txawv, xws li roj hmab thiab cov khoom siv yas |

| Muaj nuj nqi: | Tsiv qhov chaw molded nyob rau hauv ib lub voj voog |

| Txhaj tshuaj molding txheej txheem | clamping-filling-(gas-pab, dej-pab) siab--kev tu-txias-qhib-- demoulding |

| Cov ntaub ntawv tseem ceeb | P20, 718, NAK80, S136, SKD11, 1.2738, 1.2311, 718, lossis customized |

| Manufacturing Lub sij hawm: | 60 hnub |

| Lub sijhawm thauj khoom thauj: | 5-7 hnub |

| Khoom keeb kwm | Tuam Tshoj |

| Muaj peev xwm muab tau | 500 pwm ib xyoos twg |

Ob-txhaj tshuaj molding yog ib qho txheej txheem rau txheej ob lossis ntau cov ntaub ntawv sib txawv nyob rau sab saum toj ntawm ib leeg los tsim cov khoom tiav.Nws xav tau cov tshuab tshwj xeeb uas tuaj yeem ua tiav cov txheej txheem txhaj tshuaj molding ob zaug hauv ib lub voj voog.Hauv thawj kauj ruam ntawm cov txheej txheem no, ib qho khoom siv yog txhaj rau hauv pwm los tsim cov duab tseem ceeb.Cov duab no muaj qhov los yog qhov chaw, uas yog tom qab ntawd sau los ntawm cov khoom siv thib ob thaum nws txhaj tshuaj hauv qib 2.

Ob-txheej yas txhaj tshuaj molding, co-txhaj tshuaj, ob-xim, thiab ntau yam molding yog tag nrho cov variations ntawm ib tug advanced molding tshuab

Kev sib xyaw cov yas tawv nrog cov khoom muag muag

Ob-kauj ruam txheej txheem ua thaum lub sij hawm ib lub voj voog xovxwm tshuab

Consolidates ob los yog ntau tshaj cov khoom yog li tshem tawm cov nqi sib dhos ntxiv

Cov neeg tsim qauv thiab cov neeg siv khoom tas li sim siv tshiab rau cov yas txhaj tshuaj molding qhov chaw uas tsim los siv ntau cov txheej txheem molding.

Cov ntawv thov no feem ntau tshwm sim hauv cov hom hauv qab no

l high-end desktop computers

l Ntau xim molding qhov chaw

l Cov khoom siv me nyuam nrog cov khoom txav

l teeb pom kev zoo nyees khawm rau tsheb navigation units

l Cov khoom uas yuav tsum tau sealing

l Txhua yam cua txias

l Soft khoom kov